HOW WE WORK?

Cutting

Cutting machines used in production are from the German firm HOMAG, who is the global market leader for wood processing machines.

Grooving

Our experienced operators use Automatic Industry 4.0 equipment to make exact grooves in frame and panel construction to align with drawer bottoms.

Edging

We have three edge banding machines, two KDT and one Nanxing, which are the best brands in the world.

Drilling Edge Banding

We utilize three drilling machines with sensors that automatically recognize any cutting error and stops production of that product. As a testament to our advanced technology and fast production times, these machines drill over 1,200 pieces per hour.

Lacquered

Before we apply the lacquer finishing, our team will inspect the base items for color and measurement.

PVC Machine

After the cabinet gets shaped, we clean every panel to prepare gluing and then apply the PVC finishing.

Quality Inspection

We inspect production in every stage to ensure the color, accessories, size, quantities etc. are correct for each order according to the drawing specifications.

Packing

We could provide flat packing or assembled packing if needed, we could send assemble team to your site. During the sorting area and packing step, workers only need to scan the QR code, the system will prompt and ensure the sorting is correct to make sure every panel of whole project is included.

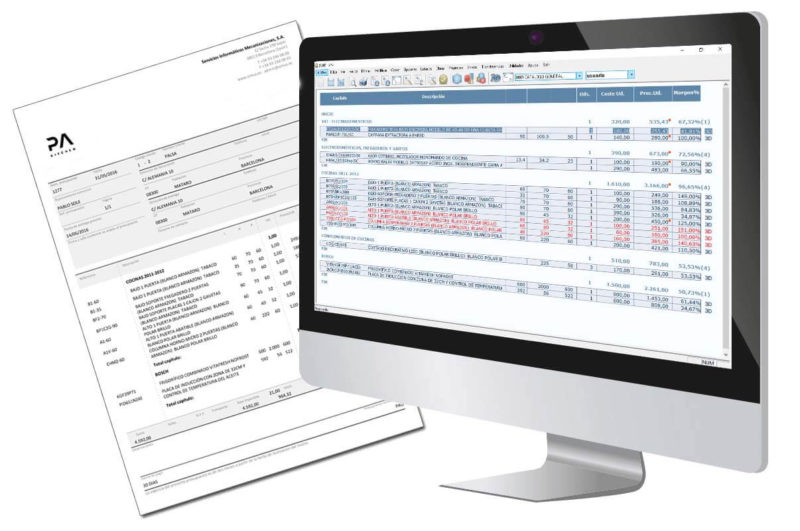

How our DESIGN SOFTWARE AUTOMATION SYSTEM Works:

The production of a perfect kitchen cabinet begins with a perfect interpretation of the design. At US Commercial Supply, our design process is seamless. Our designers cater to your project by utilizing our design & production software to draw the desired kitchen design. This design is then sent to the production department which inputs the mechanical specifications and data requirements into the machine systems. Our high-precision machines then interpret the design specifications and produce your projects.

Quick Response Code:

Each panel we produce has a tracking sticker which is scanned using our QR system and uploaded to our database. This process ensures that no item is missing before preparations are made for shipping. We take extra care while physically packing and preparing orders for shipment. We use strong, protective materials and corner protection to ensure orders arrive at their destination in perfect condition. All our packing and shipping protocols are tailored to meet international shipping guidelines.

The QR codes on the tracking sticker of each panel contain all the information about each specific order. We use these codes to track and follow your orders and ensure that no piece is missing.

US Commercial Supply utilizes the industry’s most advanced automated systems, providing us with a competitive advantage. Through state-of-the-art technology, we can keep our prices low while providing high-quality products within a short manufacturing time.